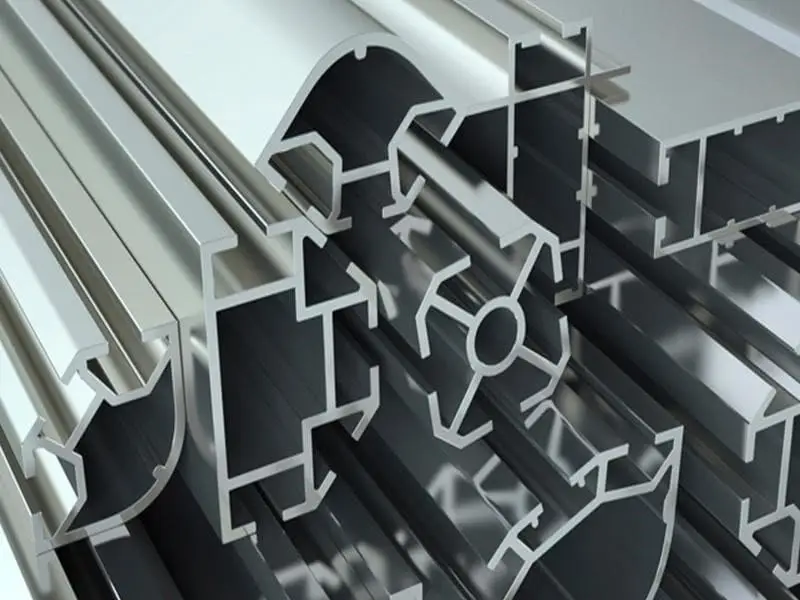

The selection of extruded aluminum profiles is one of the most important decisions for engineers, builders, and machinery manufacturers.

Choosing the wrong system can lead to deformations, structural failures, and cost overruns. In this article, we provide you with a practical guide to making the best decision and optimizing your investment.

Advantages of Extruded Aluminum over Other Materials

Unlike steel or other metals, extruded aluminum offers:

-

Lightweight: up to 50% less weight than steel, ideal for mobile or modular structures.

-

Mechanical strength: withstands heavy loads without compromising rigidity.

-

Design flexibility: profiles allow modular connections and easy adaptation.

-

Durability: resists corrosion in demanding industrial environments.

These features make it the ideal material for automation, robotics, conveyors, and industrial workstations.

Key Factors for Choosing the Right Aluminum Profile

1. Load and required rigidity

Define the maximum weight the structure will support. For light applications, a standard 20×20 profile is sufficient; however, for heavy machinery, reinforced larger-section profiles are recommended.

2. Type of application

-

Modular structures: workstations, racks, and enclosures.

-

Machinery support: frames for CNC, laser systems, or automation equipment.

-

Industrial transport: frames for conveyor belts and mobile robots.

3. Accessories and compatibility

Choose profiles with standardized connection systems that allow easy integration of connectors, hinges, wheels, and enclosures. This reduces assembly time and maintenance costs.

Common Mistakes to Avoid

-

Undersizing profiles: using lightweight aluminum in heavy-load applications.

-

Ignoring finishes: anodizing protects against corrosion and improves aesthetics.

-

Failing to plan assembly: profiles without compatible slots may limit future expansions.

Conclusion

Choosing the right extruded aluminum profile not only improves the safety and efficiency of your structure but also ensures long-term savings in maintenance and modifications.

At Disentec, we offer our 2025 catalog specialized in aluminum profiles and structural systems, designed for industrial automation, machinery, and modular construction.

Frequently Asked Questions (Conversational SEO)

What aluminum profile should I use for heavy machinery?

We recommend reinforced large-section profiles with high-rigidity joints.

Is aluminum better than steel for industrial structures?

Yes—especially in applications that require lightweight design, corrosion resistance, and modular assembly.

Download the Disentec 2025 Catalog and receive technical advice to design your next industrial structure.

Write to us and we'll respond, offering you the best service we can.