At Disentec, quality and service are not just commercial promises—they are the foundation upon which our entire operation is built. Every project, every part, and every implementation is guided by a single principle: the constant pursuit of industrial excellence. Thanks to this philosophy, we have established ourselves as a strategic partner for companies across various sectors that trust us to optimize their processes and enhance their competitiveness.

Commitment from the Start

Quality begins at the design stage. At Disentec, we plan each solution with a comprehensive approach that brings together engineering, technology, and functionality. Our technical team works closely with clients to understand their production needs, operational constraints, and long-term goals. Based on this diagnosis, we develop customized solutions that ensure performance, precision, and durability.

From initial sketches to final testing, each product goes through rigorous internal controls to ensure compliance with the highest international standards. Our processes are based on Lean Manufacturing principles, allowing us to reduce waste, optimize resources, and maintain a balance between productivity and sustainability.

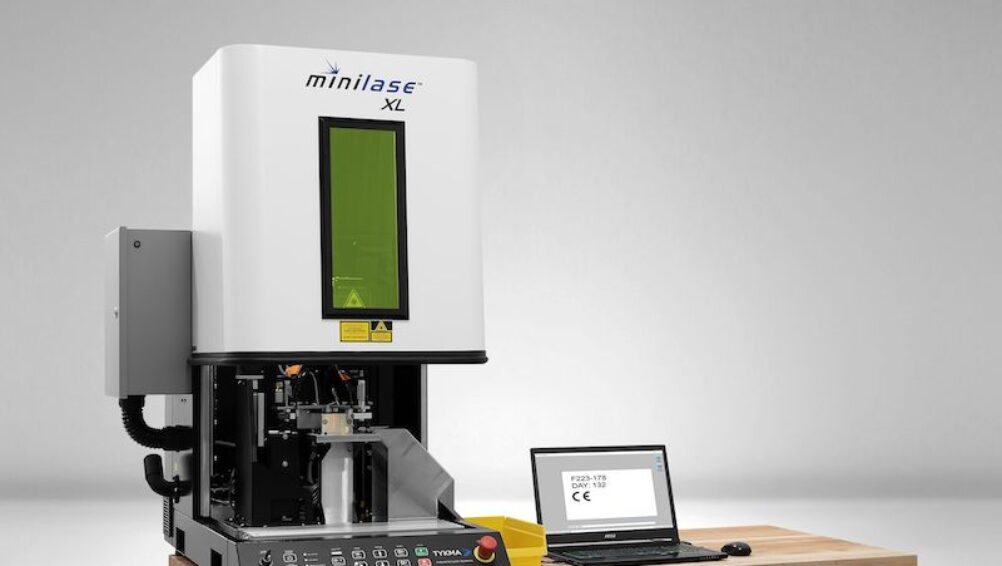

Sistema de marcado láser Minilase™ XL

.

Quality Control and Assurance

For us, “quality” doesn’t just mean something works well—it means it works consistently, safely, and efficiently in any industrial environment. That’s why we have a structured quality management system that covers every stage of the process: from material acquisition to final delivery and on-site installation.

-

Material selection: We work with certified suppliers that meet international ISO and ASTM standards, ensuring high-performance materials.

-

Controlled manufacturing: Our machining, welding, and assembly processes are carried out with calibrated equipment and constant supervision.

-

Functional testing: Each product undergoes resistance, accuracy, and performance tests before delivery.

-

Technical documentation: We provide manuals, technical sheets, and maintenance protocols to ensure the client fully understands their equipment.

This preventive approach helps avoid failures, minimizes downtime, and enhances the reliability of the implemented solutions.

At Disentec, we are proud to be the official distributor of TYKMA Electrox in Mexico, one of the world’s most recognized brands in industrial laser marking systems. This partnership strengthens our commitment to innovation, quality, and technological excellence, allowing us to offer our clients marking solutions that are precise, durable, and highly reliable.

Continuous Technology and Innovation

Commitment to quality also means staying at the forefront of technology. At Disentec, we are committed to continuous innovation, investing in research and development to stay up to date with Industry 4.0 trends.

Integrating laser systems, aluminum structures, and industrial software requires not only technical knowledge but also creativity to connect all the pieces of a modern production ecosystem.

Our systems are designed to offer millimeter precision, increased operational speed, and reduced human error thanks to automation and data intelligence.

The use of advanced industrial software allows us to monitor, adjust, and optimize equipment performance in real time. These tools enable early failure detection, preventive maintenance scheduling, and lower operating costs—ensuring that every client gets the maximum return on their investment.

Service Culture and Customer Support

At Disentec, service is a natural extension of quality. We understand that technology—no matter how advanced—is only valuable when supported by people who understand and stand behind it. That’s why we offer personalized attention at every stage of the project: technical consulting, installation, training, and post-sales support.

Our technical staff is available to answer questions, perform scheduled maintenance, and respond to emergencies quickly and efficiently. We also offer specialized training programs—both in-person and online—so our clients’ personnel can operate the equipment safely and make full use of its features.

This support model has enabled us to build strong and lasting relationships with companies in industries such as automotive, electronics, metalworking, medical, and food. Each project implemented represents a story of collaboration and mutual trust.

Continuous Improvement and Human Commitment

At Disentec, quality is not static—it is renewed every day. We have a continuous improvement program focused on innovation, sustainability, and human talent development. Our team is constantly trained in new technologies, management methodologies, and quality standards, ensuring that each member actively contributes to the company’s goals.

We promote an organizational culture based on responsibility, ethics, and efficiency, where every team member understands that their work directly impacts customer satisfaction. This sense of ownership translates into commitment, proactivity, and a passion for doing things right the first time.

Results That Speak for Themselves

Over the years, Disentec has implemented more than 500 industrial projects in Mexico and the United States. Each one represents real proof of our commitment to quality and service. The results are tangible: increased productivity, error reduction, time optimization, and a significant improvement in our clients’ operational profitability.

These achievements are the result of disciplined work, a strategic vision, and a team that understands that quality is not a department—it’s a permanent mindset.