At TYKMA Electrox, we supply a wide variety of premium laser marking systems that can boost your facility’s efficiency and provide you with a host of benefits.

These systems range in size and functionality, allowing companies to find the ideal unit to integrate into their operations. But sometimes a business requires a system tailored to a specific function or application, which is where our custom laser marking machines come in.

Read on to learn about our various custom laser marking systems that can all be modified to your specifications.

WK Series Laser Marking Systems

The WK Series is a versatile Class 1 laser marking system which features an expandable, large work envelope and can integrate numerous TYKMA Electrox laser markers, such as our Vereo. Some of the notable features of the WK Series include:

- A modular design ideal for build-to-order design, large parts, or custom fixtures and processes

- Safety interlocking and a safety viewing window

- A T-slot work surface and illuminated enclosure

- A monitor, keyboard, and mouse on a swing arm

- An operator control pendant with key start

- Floor mounts or locking mobile castors

- Fixed/power/automatic focal height adjustment

Options and accessories for these systems include:

- Rotation axis for 360° part marking

- An automatic part loading door

- Custom fixtures

- Fume and dust extraction unit

- Custom software solutions

XY Series Laser Marking Systems

The XY Series is a Class 1 system ideal for high throughput operations, as well as the marking of large parts and surfaces that require marks on multiple locations. Some of the notable features of the XY Series include:

- The ability to mark large parts or trays of multiple pieces in a single programmed operation

- Automatic XY staging for expanded marking areas

- Power/automatic Z-axis focal height adjustment

- Safety interlocking and a safety viewing window

- A T-slot work surface and illuminated enclosure

- A monitor, keyboard, and mouse on a swing arm

- An operator control pendant with key start

- Four full-size service doors

Options and accessories for these systems include:

- Rotation axis for 360° part marking

- An automatic part loading door

- Custom fixtures

- Fume and dust extraction unit

- Custom software solutions

Custom Dial Index Laser Marking Systems

The Custom Dial Index is a Class 1 system ideal for marking a wide range of products, allowing the operator to load and unload completed parts while others are still being marked. Some of the notable features of the Custom Dial Index include:

- A two-position 500mm or 800mm rotary index table

- Safety interlocking and a safety viewing window

- A monitor, keyboard, and mouse on an adjustable swing arm

- An operator control pendant with key start

- Four full-size service doors

- Fixed/power/programmable focal height adjustment

Options and accessories for these systems include:

- Custom fixtures

- Fume and dust extraction unit

- Custom software solutions

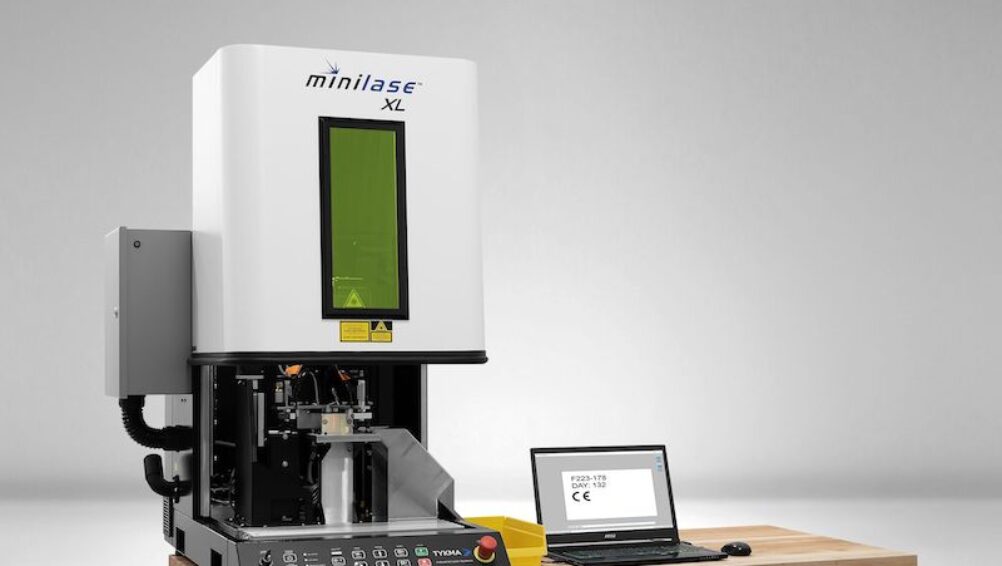

Build-to-Order Laser Marking Systems

Our Build-to-Order laser marking systems will let you find the “perfect fit” for your operations. We’ll evaluate your specific requirements when it comes to laser marking, determine which product aspects are most worthwhile, then craft your new system to meet exacting specifications, including sizing, safety, and spacing needs.

Some of the possible features of our Build-to-Order systems include:

- Automatic dataplate feeding systems

- Robotic part loading and unloading

- Automated part handling

- Custom part fixtures and trays

- Machine vision and part inspection

- Custom software and database solutions

- Integrated inline laser systems

Below, you can see one of our Build-to-Order systems in operation, the Pick and Place Nameplate and Tag Laser Marking System:

Another custom laser marking system’s operation can be seen in the following video:

Have a Need for a Custom Laser Engraving System? Reach Out to Us!

If you’re looking to incorporate a laser marking system into your operations and you want to ensure that it will fulfill everything you need, feel free to contact our team today! We’re ready to talk options and develop the perfect system for your facility.