TYKMA Electrox’s laser marking systems can operate on a wide variety of materials, including one of the toughest and most used materials in the world: steel.

Steel markings are needed across many industries, used in everything from UDI medical devices and oil and gas applications to tools, automotive parts, heavy equipment and more. For companies who work in these industries, or regularly supply parts to clients in these fields, having a reliable system for laser marking steel is key.

What Are TYKMA Electrox’s Capabilities for Laser Etching Steel?

With our versatile machines, a variety of marking processes can be performed, depending on your company’s specific needs. So if you are in need a quality machine for laser marking steel, or are in need of a system for etching or engraving, you’re in luck!

When it comes to steel parts, our processes include:

- Burning/General Marking

This type of steel marking is created by aggressively burning the surface of the material. Depending on the substrate, the mark will vary in color from medium brown to black or black/grey. The surface of the material will feel rough to the touch and feature areas of rise and fall.

- Annealing/Black Surface Marking

This type of steel marking is created by applying a large amount of heat to the surface of the material while minimizing the aggressiveness of the mark. The result is a solid black mark with a smooth surface finish. This type of marking is very common for medical applications. - Frosting/White Surface Marking

This type of steel marking is created by frosting the surface of the material at high speeds. This usually results in a bright or white color. The mark may have a slight texture to the touch, but the surface or coating penetration is minimal, if present at all. - Deep Engraving/Material Removal

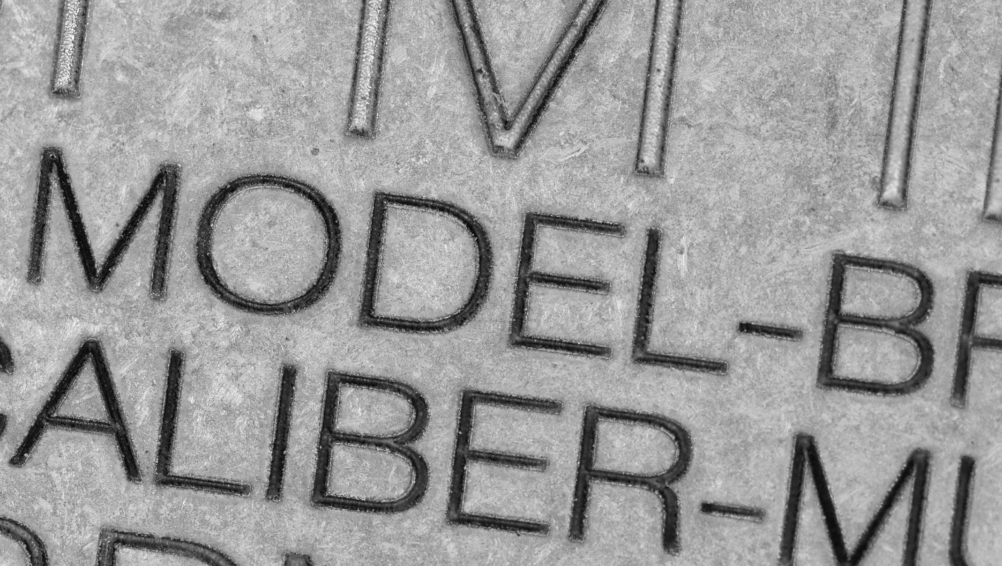

This type of steel marking is created by removing material to create a mark that has depth. The resulting mark has an embossed look and the mark depth can vary from minimum to extreme depending on the time allowed for the marking process. Stripping small layers to achieve the desired depth is preferred.

A Look at Our Machines for Laser Etching Steel

With advanced MOPA fiber laser technology and environmentally friendly efficiency, TYKMA Electrox laser systems are perfect for any and all marking applications, particularly laser marking steel.

Other advantages of TYKMA Electrox systems for laser engraving steel include:

- Air-cooled, ergonomic, maintenance-free designs with user-friendly controls

- True reliability (a lifespan up to 100,000 hours with a three-year warranty)

- Advanced capabilities to solve the most difficult steel marking applications

Flexible performance capabilities give our systems for laser engraving steel the unique ability to combine both power and precision. No matter the type of industrial application, a TYKMA Electrox system will mark, engrave or etch with the quality you need.

What Are the Differences Between Engraving, Marking, and Etching on Steel?

We are glad you asked. Many often do not know that laser marking, engraving, and etching are all different techniques! Be sure to check out our informative blog post to learn the key differences between these three commonly used applications.

Learn More About TYKMA Electrox’s Steel Marking Machines

It is our job to ensure that you get the system for laser marking steel that perfectly suits your company. And with our 24/7/365 customer support team, we will always be available to provide set-up support, training, troubleshooting and maintenance!

To find the right steel laser marking system for you steel application needs, be sure to contact TYKMA Electrox today!