As we discussed in a previous blog post, speed, accuracy and reliability are the cornerstones of plastic extrusion lines. To meet the needs of this specialized application, the laser requires a support system to assist with integration and alignment with the greater production line.

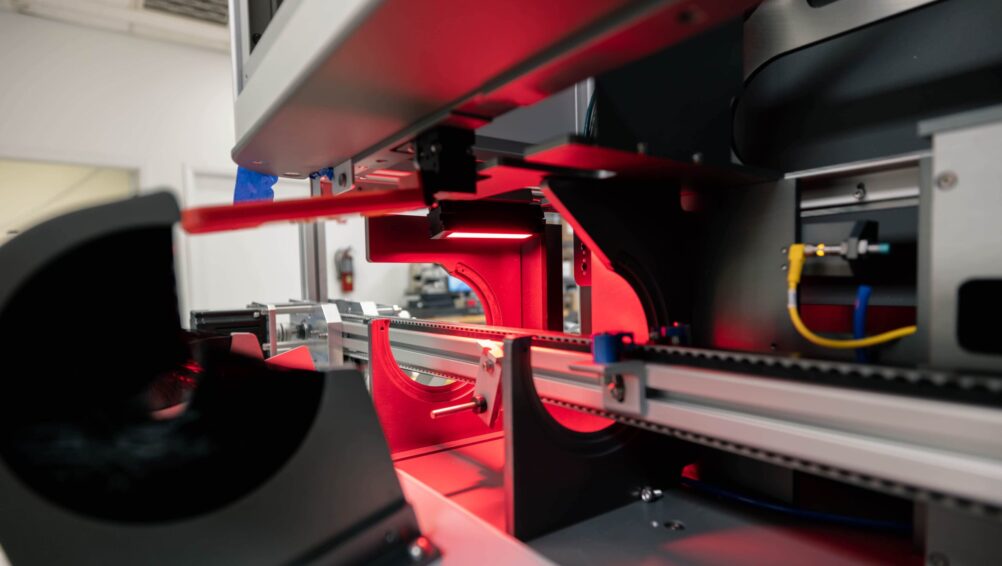

We recently developed a laser application to integrate and automate an On the Fly on the fly laser slitting system into a continuous irrigation drip tape extrusion line. There were unique challenges to this application and we worked with the client to develop a solution that met their needs.

In this post, we’ll take a look at two key pieces of this integration – the laser control system and vision system – and how they enhanced the irrigation drip tape extrusion line for this application.

Extrusion Line Laser Control System

A laser control system is the backbone of any laser system. The software operates the laser and manages the other automated elements of the system. Speed, alignment with the rest of the production line, and accuracy are essential for an extrusion line.

We customize each laser control system to meet the needs of the client and the application. Let’s look at the specifics of the laser control system we recently designed for laser slitting of irrigation drip tape.

User-friendly programming interface

A user-friendly programming interface and production line communication provides fast and easy setup. Building flexibility into the client’s system enabled short change-over times for different process configurations. In day-to-day operation of the system, a technician can easily adjust for different product requirements.

Our proprietary software can even be designed with several user levels to accommodate a busy manufacturing floor. This ensures the system’s specifications are only changed by authorized employees.

As a laser integrator, we work with our clients to ensure all elements of the laser system (laser, automation, software) are compatible with the rest of their manufacturing process. As one part of a complex extrusion line, our goal with our client was to design a laser control system that’s flexible and communicative. By streamlining the process as much as possible, the client was able to maintain a high level of productivity.

Quality assurance

Quality is a priority for any manufacturing line. In the case of irrigation drip lines, it’s critical for the laser to cut slits with extreme accuracy. If the slits are not cut correctly, the final product will not irrigate properly and will leave dry spots on a field or garden.

Using the programming interface, a skilled technician can select the parameters for the run – length and width of the slit (3-5mm), placement of the slit (typically 6, 12, 18 inches apart), diameter of the tubing, and desired irrigation rate. The ability to define specifications clearly and easily within the interface drives accuracy throughout the product run.

Velocity

Constant velocity and momentum are the signatures of an extrusion line. Developing a laser control system that can communicate with other elements of the line was necessary to ensure the laser aligns with the rest of the extrusion line.

Our most recent drip irrigation tape extrusion line laser system operates in excess of 1,000 feet per minute. However, max speed is often dictated by the other elements of the extrusion line, rather than the speed of the laser.

In order to align with the system’s speed, the speed of the line is measured through feedback to the laser control system and tracked dynamically throughout the process. This ensures the laser is consistently slitting (or marking) in the correct locations.

Extrusion Line Vision System

In concert with the laser control system, laser slitting of irrigation drip tape relies on a vision system to ensure authentication of the final product. The vision system provides closed loop feedback to the laser control system. Vision information is used by the laser to steer the laser to the appropriate midline and make an accurate cut.

While on the extrusion line, the slits need be made down the middle of the tube as much as possible. This can prove challenging as the extrusion line keeps the product in constant movement – twisting, jumping around due to speed and lightness of the product are all important variables. The vision system helps to locate and align the tape to ensure the slit is placed consistently in the correct location.

Together, the laser control system and vision system feedback provide accurate placement of the slit and verification that the geometry falls within process limits.

Final Thoughts

All of our laser systems start with finding the right laser source; from there, it’s about building a support system that enhances the role the laser plays and integrates with the rest of the manufacturing line.

The On the Fly laser system we developed for laser slitting for irrigation drip tape resulted in high production throughput with excellent accuracy and repeatability, which led to a higher yield and excellent customer value. The laser control system and vision system were essential to achieving these results.

The hard work of our engineers in our Applications Development Lab laid the foundation for the optimal solution for our client’s extrusion line manufacturing challenges. Then, our mechanical engineering department, software department, and machine shop, built on that foundation to develop the complete solution to meet the client’s needs.

Do you have a plastic extrusion line that requires a laser-based solution? Contact us today to discuss your needs and specifications.