October 5 brings yet another National Manufacturing Day, an event manufacturers, innovators, engineers, and technicians look forward to for the opportunities it provides. Every year, companies from all over the United States host events, present live demonstrations of products, offer educational seminars, give tours, and meet with members of their community and interested parties.

Because of the increased interest in the field generated by National Manufacturing Day, a wide variety of articles will be written about not only the event itself, but manufacturing concerns as a whole.

We thought this occasion would be a good time to present a piece on the history of U.S. manufacturing, chronicling it from its infancy in the late 1700s to its status today. Give it a look!

1700s to 1800s

Prior to the late 1700s and early 1800s, manufacturing was drastically different than how we think of it today.

Anyone who’s been to Colonial Williamsburg or similar “living history” parks will recall the craftsmen and craftswomen talking about their trades. Household and individual manufacturing efforts such as those discussed by these actors were mostly the extent of the field at this time.

It wasn’t until key innovators emerged and the Industrial Revolution got underway that manufacturing transformed into something resembling its present form. A few key milestones:

- 1785 – Bulk material handling is introduced when Oliver Evans builds an automatic flour mill that incorporates a leather belt bucket elevator, screw and belt conveyors, and other mechanized equipment.

- 1790 – The first factory in America is built by Samuel Slater, a cotton-spinning mill located in Pawtucket, Rhode Island, utilizing production methods he learned in England.

- 1792 – Eli Whitney invents the cotton gin which separates fibers from seeds, boosting productivity within the vital cotton industry.

- 1798 – Whitney forever changes manufacturing when he begins making firearms with interchangeable parts, forever altering the production of goods.

- 1804 – Oliver Evans introduces a high-powered steam engine that has applications in a variety of industries. Ships, flour mills, printing presses, textile factories, and sawmills all utilize the device for their power needs.

- 1820 – The American Industrial Revolution begins with coal power, machine production, and canal and railway construction all drastically increasing opportunities for production, profit, and mobility.

- 1830 – The first American steam locomotive is unveiled. Called the “Tom Thumb,” it is put to the test in a race against a horse-drawn cart to illustrate the superiority of steam engines.

- 1850 – The interchangeable parts popularized by Eli Whitney gain further traction as the American System of Manufacturing is adopted. This methodology quickens the pace of companies’ manufacturing efforts and leads to processes that still exist to this day.

Early 1900s

Much of the early 20th Century saw an increase in manufacturing for modes of transportation as well as an expansion of the capabilities for factories.

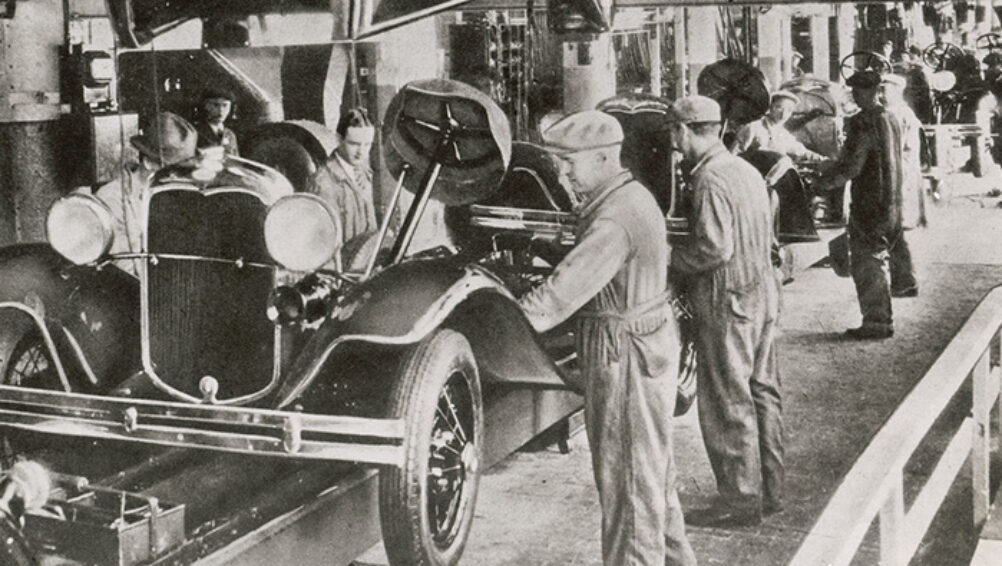

- 1908 – Car manufacturing begins in the United States with the Ford Motor Company producing the first Model T’s on their assembly line. To keep a uniformity and speed in production, all of the cars were offered only in a single color, leading to Henry Ford’s famous line to consumers: “Any color as long as it’s black.”

- 1913 – Ford revolutionizes manufacturing by introducing a moving assembly line, forever speeding up his company’s production and that of countless others to come.

- 1930s – Toyota is the first company to develop Just-in-Time manufacturing (JIT) which is later expanded upon in the Lean Manufacturing movement. The goals of JIT are to minimize waste while ensuring productivity.

- 1942 – The first jet engine is developed by GE engineers known as the “Hush-Hush Boys.” After ten months of nonstop work, their jet engine is ready to play its significant role in America’s World War II efforts.

Post World War II

Following World War II, women who had entered the workforce as part of the war effort often stayed on in their roles, bringing changes to both manufacturing and society at large. Other innovations included increased streamlining of operations and the adoption of computerized technologies.

- 1953 – Computer-aided-design, or CAD, first comes into play with select shapes within a production process being formed by a digital machine tool.

- 1958 – The first integrated circuits, or computer chips, are developed allowing for a greater level of processing and opening the doors to increased automation within factories.

- 1970 – OSHA, the Occupational Safety and Health Act, is established which introduces safety protocols for the workplace, with manufacturing being a particular sector of focus.

- 1973 – The first industrial robots are implemented in Europe with the U.S. soon adopting the technology thereafter.

- 1981 – The personal computer is introduced to the public by IBM, leading to increased efficiency within the workplace and a host of future functionalities as computer models improved.

21st Century

Following the 1980s’ and 1990s’ developments in miniaturization of many products, American manufacturing took new strides and became more intricate.

- 2002 – The U.S. Manufacturing Enterprise Integration Act of 2002 is enacted which allows for development of a Smart Manufacturing Infrastructure.

- 2007 – Apple unveils the iPhone, paving the way for a variety of smartphones, tablets, and other smart devices, and forever altering the way consumers live their lives and companies connect with them.

- 2013 – Though 3D printing technology originally emerges in the 1980s, it isn’t until well into the 21st Century that the tech became advanced enough to be used widely. By 2013, a host of companies had incorporated 3D printing into their operations.

- 2010s and Beyond – The Internet of Things, or IoT, will continue to have a huge impact on numerous industries, including manufacturing. With devices being further integrated with each other, and speed and convenience increasing because of it, companies should experience boosts in productivity at their facilities.

About TYKMA Electrox

TYKMA Electrox has a lengthy history within the manufacturing sector, with components of our business stretching back more than forty years.

Electrox began in the 1970s and was the first to develop and manufacture a commercial fast axial flow CO2 laser, eventually emerging as one of the premier, worldwide direct sale and OEM suppliers of Nd:YAG laser marking systems. TYKMA began operations in 2001, originally as a distributor of German manufactured industrial marking technologies.

After TYKMA initiated an in-house focus on the development and manufacture of laser marking systems during the 2000s, TYKMA and Electrox merged to form TYKMA Electrox in 2015. As of 2016, TYKMA Electrox is fully integrated as one organization worldwide offering top-class laser marking systems to diverse businesses, including fellow manufacturers.

Contact Us

Have questions about all we can provide for you and your company? Reach out to our team today!