Control Micro Systems, Inc. recently re-engineered its line of laser marking systems designed specifically for integration with high speed extrusion lines.

Plastics extrusion is a high-volume manufacturing process in which raw plastic is melted and formed into a continuous profile.

Extrusion produces items such as pvc pipe/tubing, weather-stripping, fencing, deck railings, window frames, plastic films and sheeting, thermoplastic coatings, and wire insulation. Many extrusion lines require marking of product identification information, product sizing, compliance with government regulations and traceability identifiers. The marking technology must be permanent, high-speed, preferably without inks or other additives, and capable of operating 24/7.

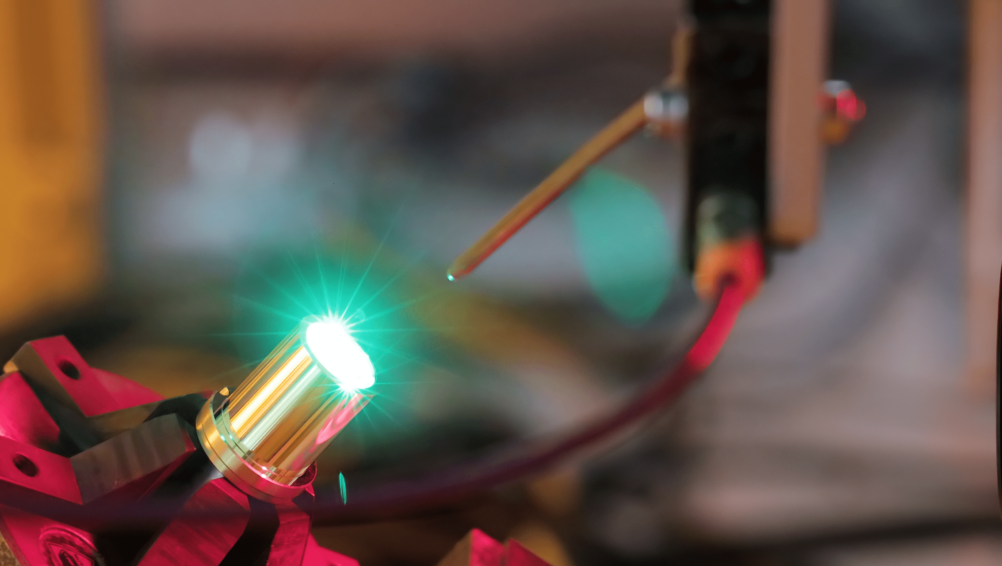

Control Micro Systems has developed a system platform that can be equipped with either a CO2 laser source (10,640nm), Ytterbium fiber (1,064nm), frequency-doubled Nd:YVO4 (532nm) or frequency-tripled NdYVO4 (355nm UV) laser source to laser mark virtually any plastic chemistry or color. Control Micro Systems control software and optics system has demonstrated marking of text, graphic images, machine readable 2D matrix and barcodes at extrusion speed in excess of 800 feet per minute.

Control Micro Systems has installed extrusion line laser marking systems globally including the production of polyethylene irrigation tape, rigid pvc gas lines and medical tubing.