Creating clean and clear marks in manufacturing has never been more important. With the tracking and identifying requirements continuously evolving, manufacturers are looking for reliable and effective ways for marking their products. There are a variety of methods for marking product surfaces, though it can be difficult to determine which is the best option for your company.

Lasers have proven to be an excellent and reliable way to mark on products and materials, but how do they compare to other types of marking technologies and methods?

Today, we will look at the four main types of marking technologies: laser, dot peen, inkjet and electrochemical. We will see how each alternative method compares to laser marking and which could be the most accurate and effective solution for your application.

Laser Marking vs. Dot Peen Marking

Dot peen marking is the process of utilizing varying levels of force to puncture or “peen” the surface of metal, aluminum, plastic, and other materials with small dots.

The succession of these dots results in images for digits, text, logos and 2D data matrix codes, which are indented into the product surface and viewable from certain angles.

Lasers, on the other hand, offer three different ways to create identifying marks on products:

- Laser Marking – In this process, a low-powered beam is moved across a material slowly to create discoloration without disrupting the material

- Laser Engraving – This process uses high heat, which essentially causes the material to vaporize, creating a cavity in the surface that is noticeable to the eye and touch

- Laser Etching – High heat is used to melt the surface of the material, which causes the material to expand and create a raised mark

Each laser marking method creates a distinct mark that is visible to the eye using a series of mirrors to focus the laser beam.

How Do They Compare?

While both laser marking and dot peen marking can create permanent solutions for your products, there are also a few differences beyond how the markings are created.

- Accuracy – With dot peen marking, the indents and peaks on the product surface can be difficult to read at certain angles and in some lighting, while laser marking machines create far more readable and accurate marks.

It also helps that lasers typically mark in a square cell configuration, which is easier on the eye and more legible than the round dot imprints of dot peen marking.

- Materials and Surfaces – Both dot peen and lasers can be used on a variety of materials; however, harder materials that utilize dot peen end up with shallower marks. There can also be issues with surface finish for dot peen marking. For instance, painted surfaces may be marked, but the paint may chip.

Dot peen marking works best on surfaces with a smooth finish, and cannot be used to create barcodes on products.

Laser marking, on the other hand, works on a wide variety of materials and coatings, including galvanized metals, ABS plastics, anodized aluminum, painted materials and so much more.

- Affordability – Dot peen marking machines are typically more affordable than laser marking machines in the short run. As technology develops, however, dot peen machines may prove to become obsolete.

Laser marking machines will remain relevant for years to come as technology continues to improve on their marking capabilities, making them a more worthwhile investment.

It’s also important to factor machine wear and tear into the overall price and value. With dot peen machines, the stylus tip can wear and chip over time, especially when marking on harder materials, requiring more replacement parts than a laser marking system.

Although dot peen machines may be more affordable in the short run, a laser marking machine will be a better investment in the long run.

- Mobility – Laser marking systems are typically either desktop or standalone machines, some of which include wheels in order to transport them throughout the facility.

Dot peen machines also come in tabletop units, but do offer more portability with handheld units. The handheld units typically require cords or cables, however, which can restrict portability and efficiency.

Continued innovation within the laser marking industry has resulted in more compact designs and standalone interfaces, which remove the PC requirement in order to operate the machine, making the systems easier to move around the facility.

- Speed – While both laser marking systems and dot peen markers offer a fast solution for marking products, laser marking machines work a bit faster. The difference is a matter of seconds, but if you are trying to mark large quantities of products and parts, the time can add up.

This is another instance where it is important to factor in the wear and tear of the machine because if the stylus of the dot peen system chips and needs replaced, that is time taken away from your facility’s efficiency.

With laser marking systems, you typically get a longer lifespan, which keeps your operations running more quickly and efficiently.

As you can see, while dot peen marking might produce permanent markings, you will get clearer, better quality markings with a laser marking system.

Laser Marking vs. Electrochemical Marking

Electrochemical marking, also known as chemical etching, is a process that requires a mask/stencil, an electrolyte solution, and an electrode marking head.

Through a kind of “forced corrosion,” an “oxide” black mark is created using the mask in varying degrees.

- The marking mask/stencil is soaked in the electrolyte solution and placed on the surface of the product or part

- Following this, the marking head releases a weak current into the metal surface through the marking mask

- This process is repeated until the desired marking penetration or darkness is reached

The depth and coloring of the markings can vary depending on a number of factors including the length of time, the solution, and the base metal.

The steps for laser marking are much simpler, with the marking requirements sent digitally to the system through the system’s software.

How Do They Compare?

Unlike dot peening and laser marking, chemical etching and laser marking differ to a much greater degree and in a wider variety of ways.

- Speed – Because the process needs to be repeated to reach the desired result, chemical etching can take anywhere from a few seconds to a few hours. It’s also important to note that a new marking mask is needed for each different mark, which can slow down production.

The laser marking process, as previously stated, takes only a few seconds to complete, resulting in a more efficient way to mark large quantities of products and parts.

- Environmental Impact – The chemicals and solutions used in electrochemical etching need to be properly disposed of either using wastewater treatment equipment or a certified third-party company. If not disposed of properly, these chemicals will go straight into the public water system.

In addition to not using any chemicals, laser marking systems, specifically fiber lasers, are much more efficient than other methods and use less energy. Also, some systems use little to no energy in stand-by mode, further increasing the environmental benefits.

- Affordability – Similar to with dot peen systems, laser marking presents a higher price initially when compared to chemical etching, but its long-term benefits make it the more affordable choice overall.

With chemical etching, you must also include the cost of the stampings and chemicals, plus the liability and cost of the filtration system, and/or the chemical disposal company.

- Materials and Surfaces – As previously discussed, laser marking machines can be used on a wide variety of surface coatings and materials. Chemical etching can really only be used on conductive materials.

- Accuracy – The quality of the marks, most importantly, can vary with chemical etching. It depends on the solution absorption rate and the flatness of the surface. Even then, it can take multiple applications, which can result in a lack of uniformity of parts.

Lasers have the ability to create high-quality marks with cleaner edges and distinct clarity.

Again, when comparing laser marking to chemical etching/electrochemical marking, laser marking systems are a more reliable, cost effective way to permanently mark products and parts.

Laser Marking vs. Inkjet Marking

Similar to electrochemical marking, inkjet marking uses a consumable to mark onto the part or product.

Inkjet marking is a non-contact marking process that forces pressurized ink through a nozzle to create a marking. There are two types of inkjet systems: drop on demand (DOD) and continuous ink jet (CIJ).

- Drop on Demand – Uses an array of nozzles to deposit a dot on the material without steering. The resolution and mark size is determined by the spacing of the nozzles and the size of the arrays.

- Continuous Ink Jet – Rows of charged ink droplets are dropped onto the product surface and then deflected perpendicular to the part movement in order to create dot-matrix characters. Height is determined by the voltage applied to each individual drop, while the width of the character is determined by the printer’s stroke rate and the line speed of the moving product.

With both the DOD and CIJ inkjet types, the product or part must be moving to create the mark and the ink must be baked after marking to set in place.

In the laser marking process, the part or product can remain stationary and no consumables, such as ink or chemicals, are needed.

How Do They Compare?

Inkjet marking and laser marking differ on a number of levels, including some of the most basic qualities that you may be looking for in marking technology.

- Accuracy – Although inkjet marking is the one type of marking that allows you to mark with colors or UV-only readable marks, the quality of the marks tends to be quite low. Graphics and 2D data codes are much more difficult to create than with laser marking applications.

Also, it’s important to note: inkjet marking is not permanent.

Unlike laser markings, inkjet markings can fade under UV light or rub off over time, while lasers provide permanent markings that will remain intact as long as the substrate’s surface maintains integrity.

- Speed – Laser marking allows you to mark parts and products quickly and efficiently. In comparison, Inkjet marking is a slow process, which still requires baking/setting time for the ink after the marking is complete.

Plus, with the equipment being less reliable than that of laser marking equipment, it can definitely cut into operating time.

- Affordability – While inkjet may have a lower cost than laser marking initially, the cost of the ink, equipment and disposal of the consumables does add up and can ultimately make inkjet marking more expensive overall.

- Materials and Surfaces – Inkjet marking is ideal for marking on fabrics, but overall its uses are limited in terms of the materials and surfaces it can be used on.

For some materials and surfaces, the adhesion of the ink can be difficult, and even when the ink does adhere to the material, the marking will rub off or fade over time.

- Health and Environmental Impact – When using liquids such as solvent bases, ink consumables and clearing fluids in your processes, you run the risk of creating environmental and health issues. These can occur for both usage and disposal, especially with solvents such as methyl ethyl ketones (MEK’s).

While there are safety requirements you must follow in laser marking, the environmental impact is much lower with laser marking processes.

- Maintenance and Convenience – Ink jet marking simply can’t compare to laser marking when it comes to these aspects. Clogging frequently occurs with inkjet systems, making the lines go down and significantly reducing productivity. Also, inkjet systems need to be cleaned regularly.Laser marking systems by contrast don’t face these issues since they don’t incorporate the consumable materials inkjet systems do, saving significant cost and preventing headaches and downtime.

Inkjet marking may be a good option for a temporary solution, but when looking to create permanent markings to meet tracking and identifying requirements, laser marking is the best option, hands down.

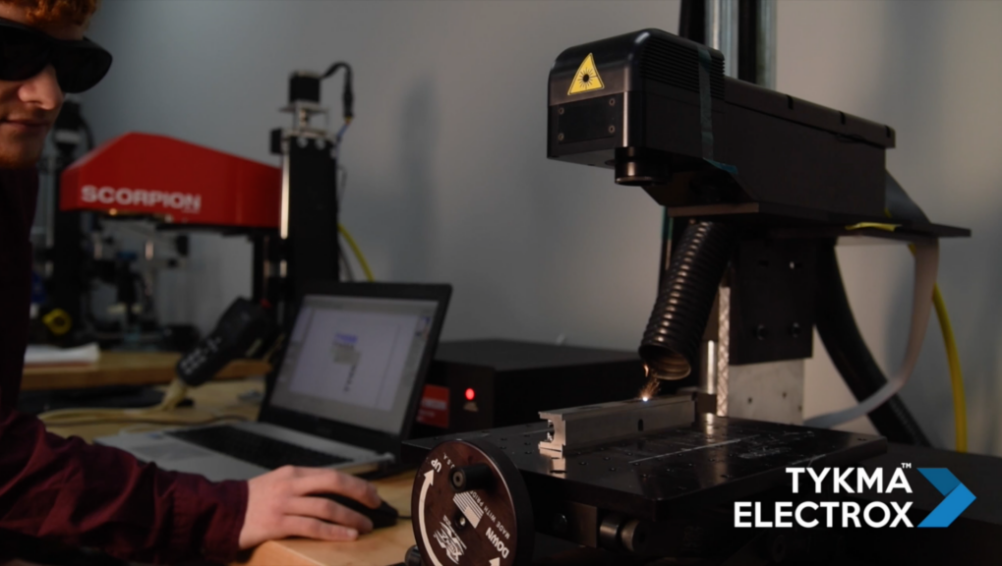

Why TYKMA Electrox’s Laser Marking Systems Are the Best of the Best

Now that we know that laser marking is the best way to create permanent, clear markings on products and parts, why not choose the best in laser marking systems: TYKMA Electrox.

TYKMA Electrox is a world leading manufacturer of laser marking systems, providing the latest in MOPA fiber laser technology, backed by excellent customer service and a three-year warranty.

Our maintenance-free design eliminates the need for changing lamps, water cooling and complex alignments. TYKMA Electrox laser systems also provide you with increased power, better pulse control, and advanced marking capabilities for more difficult marking applications.

Each of our systems is designed and built in-house to ensure outstanding quality and service.

Contact Us

To learn more about our high-quality laser marking systems and how they compare to others in the industry, please contact us today.