Often when we utilize a specific technology for a given task, our focus is on the efficiency of the equipment and whether or not it produces the results we desire. How it works isn’t our chief concern – just as long as it works, period.

But after working with equipment for a while, or when we’re investigating a new technology to incorporate into our operations, we may start to dig a little deeper and examine specifics of the equipment’s functionality.

With this in mind, we at TYKMA Electrox thought it would be helpful for our clients and future clients to learn about the key distinctions between laser classifications so they can better know and appreciate their laser marking systems.

About Laser Classification

The American National Standards Institute sets recommended guidelines for the proper and safe use of lasers that fall between the wavelengths of 180 nm and 1000 nm. These guidelines pertain to the environment the laser is found within and the environment around the laser beam’s path, and are outlined in ANSI Z136.1-2014.

These guidelines are additionally overseen and approved by the Laser Institute of America, an organization focused on laser safety programs in the United States with educational opportunities and training available for those within the laser industry.

Classes

In the current industry classification system, lasers are divided into four key classes with several sub-classes included.

Class 1

Class 1 lasers are considered safe under all conditions of normal use, and include both very low-powered lasers and those higher-powered lasers encapsulated within a housing unit that provides proper safety measures.

The maximum permissible exposure (MPE) cannot be exceeded when an operator is viewing the laser’s operation with the naked eye or while utilizing magnifying optics. This classification also denotes NOHA, or no hazard area.

Class 1M

Class 1M lasers are also considered safe under all conditions of normal use, but cannot be passed through magnifying optics like telescopes and microscopes safely. Thus, these lasers have a no hazard area for the naked eye but do have a hazard area when optical instruments are utilized.

Class 2

Class 2 lasers are those that have been deemed safe due to the human blink reflex, which will naturally respond to bright lights by limiting exposure to approximately 0.25 seconds. Should someone attempt to intentionally suppress this blink reflex and stare directly at a Class 2 laser, eye damage could occur. These are considered visible low-power lasers and feature no hazard area in regards to unintended exposure. Laser pointers are often Class 2 lasers.

Class 2M

A Class 2M laser meets the same requirements of the Class 2, however these lasers cannot be viewed through optical instruments (much like Class 1M) because the blink reflex cannot ensure safety.

Class 3R

Class 3R lasers (replacing the previous designation of Class 3A) are low-powered lasers that are safe when handled with care and when utilizing restricted beam viewing. For this class of lasers, the MPE can be exceeded but the risk of injury is quite low.

Class 3B

Class 3B lasers are medium-powered lasers that are hazardous to the naked eye with direct exposure. Diffuse reflections that can be produced from paper and matte surfaces do not pose any health risks, however. Class 3B lasers necessitate the use of a key switch and safety interlock and normally require safety goggles during any direct viewing of the beam. While there is a hazard area for the naked eye, there is no hazard area for skin.

Class 4

Class 4 lasers are the highest-powered and most dangerous class of lasers and require exacting safety protocols to prevent any operator or viewer injury. Class 4 lasers are capable of burning the skin, and creating permanent eye damage through either direct, diffuse, or indirect viewing of the laser beam.

Additionally, these lasers, if not handled properly, have the ability to ignite combustible materials leading to a potential fire risk. Indirect and non-specular reflections of the laser beam can also produce these hazards, meaning utmost care must be taken in controlling the beam’s path. To fulfill safety requirements, all Class 4 laser systems must be equipped with a key switch and safety interlock.

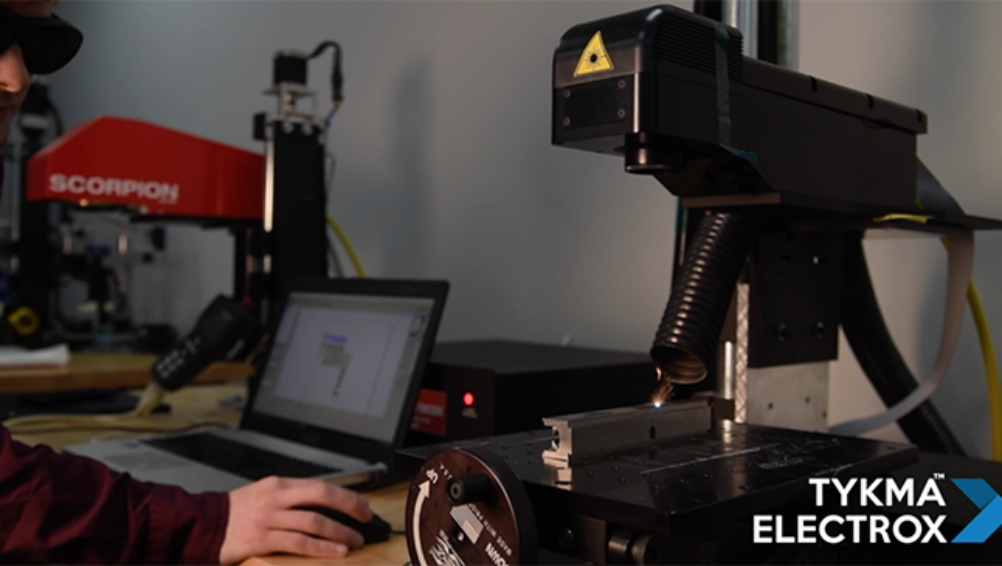

TYKMA Electrox Laser Marking Systems

Now that you know about the essential differences in laser classifications, let’s take a look at what TYKMA Electrox can provide for your operations.

Our systems fall within the Class 1 and Class 4 categories, with certain units being Class 1 systems that are able to be utilized for Class 4 purposes when the need arises.

Our Class 1 Systems

These TYKMA Electrox laser systems feature laser beams that are housed internally within the units to ensure safety, and incorporate a tinted viewing window for operator observation.

- Minilase™

- Minilase™ Manual

- Zetalase™

- Zetalase™ XL

- EMS400

- Custom Laser Machines – WK Series, XY Series, RT Series, Build-to-Order

Our Class 4 Systems

These integration lasers operate in a Class 4 designation, not being housed within an internal unit.

Our Versatile Class 1/Class 4 Systems

The following systems are designated as Class 1 systems but additionally have the capability to be used for Class 4 operation.

- Minilase™ XL – A service key allows for marking when the pneumatic door is in the up position to facilitate oversized parts

- Zetalase™ XLT – A service key allows for marking when the pneumatic door is in the up position to facilitate oversized parts

- Minilase™ Keon – A four-sided, collapsible power shroud is utilized during Class 1 marking, with a password-protected control for switching to Class 4 marking for oversized and irregular parts

Have Any Other Questions?

If you’d like to know anything else about laser classifications, the specifications and capabilities of TYKMA Electrox’s laser marking systems, or anything else, be sure to reach out to our team today. We’ll be happy to help!