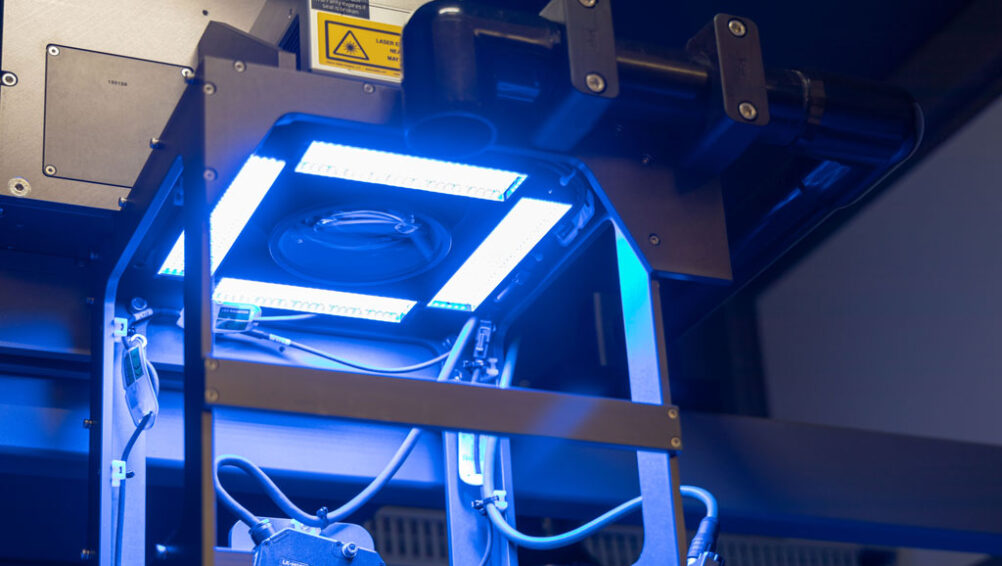

Vision systems are increasingly incorporated into laser machine tools to inspect, identify and guide laser processes.

In its simplest iteration, readers can retrieve data from product labels or documentation to obtain information relevant to the laser process. Data strings can confirm the identity of the part; specify the quantity of parts to process or designate the beginning/ending serial numbers.

For more advanced implementation, vision systems can locate the part and determine its orientation to accurately position the process (marking image, drilled hole, weld path, etc.) on the part. Analysis of the part silhouette can also verify the identity of the part to avoid costly mismatch between the part and the process. Vision can guide automation such as a robot in retrieving a part and positioning it in the laser field with high accuracy. Use of fiducial marks or other identifiable features can also be used to locate the laser process with high precision.

After processing, a vision system can verify the presence, location, quality or dimensions of the results such as measuring the contrast of a mark or the diameter of a laser drilled hole. The content and contrast of a laser marked image can be confirmed including verification of machine code compliance with the ECC200/ISO/IEC TR29158/AIM DPM standards. Vision can provide 100% fault detection on high-speed conveyors such as pharmaceutical tablet drilling lines.

While a single camera system can be used for locating objects in 2-dimensional space, a stereo vision system or 3D displacement sensor can be used to accurately locate a part or work surface in 3-dimensional space. Robots, 5-axis positioning systems, or hexapods can then be used to align the laser focal plane to the object work surface. The same technology can be used to sort randomly stacked parts or identify defects prior to processing. With etching, engraving, or drilling processes, 3D analysis can quantify the end result.

Laser technology is an excellent choice when automation, speed and precision are required. Employing pre- and post-processing vision can further enhance the accuracy of the process, avoid costly manufacturing errors and insure product quality.