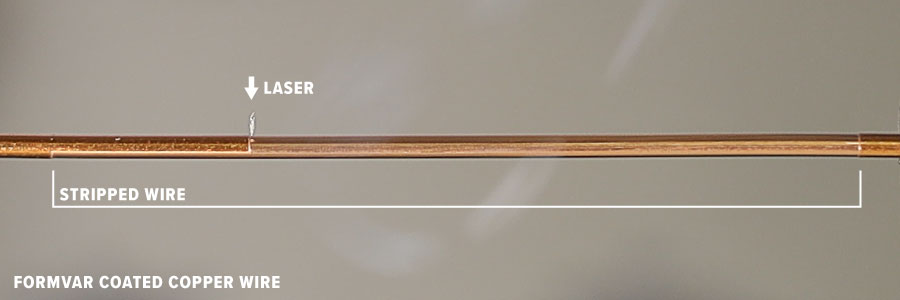

Coated wires are used throughout the medical industry and need to be end stripped and window stripped to exacting tolerances for eventual soldering, brazing or welding. Insulating coating types such as polyimide, urethane, lacquer, Kapton® and formvar are commonly used on medical wires and require unique methods to be cleanly removed. These materials can’t be scribed and peeled like other standard plastic insulation and must be fully ablated.

Our Laser Process

At CMS Laser, we have designed laser stripping systems to process wires with these coatings and have had success removing them cleanly without overheating the inner conductor. We use a CO2 laser (9.4, 10.2 or 10.6 µm) when stripping these types of wires because high absorption of these wavelengths in the coating material causes rapid ablation of the coating without damaging the underlying metal wire. Minimizing the heat-affected zone (HAZ) in coatings is a medical industry requirement and is essential to a comprehensive process solution.

Lasers are an efficient, safe and accurate way to strip coated medical wires of all gauges and geometrical cross sections. We have recent experience working with wires down to 44 AWG but can work with smaller wires if needed. Using lasers to strip these types of wire eliminates the need for harsh chemical baths or wire-damaging mechanical methods. Lasers deliver precise and programmable strip lengths that wouldn’t be possible with other technologies.

Depending on the strip length requirements and wire type, our laser stripping method can be combined with our On-The-Fly processing capabilities. Small spaced windows or long continuous areas can be stripped while the wire is moving. Long coated medical wires can be stripped completely in minutes. For automated systems, wires on spools or in troughs can be handled.

Hand load systems are also common and are especially useful for pre-assembled wire harnesses. Some systems can even be designed to strip multiple wires at the same time to improve throughput or ease of handling. Our standard wire stripping systems serve a large range of applications, but our engineers can also design a custom system to meet your unique handling requirements.

In many cases, post-stripping camera vision systems can also be integrated onto the laser system to verify that the wire was successfully stripped to required specifications. Using optimized lighting and camera arrangements, the difference between stripped and unstripped areas can be inspected and logged. Real-time or offline adjustments can then be made if needed.

Our applications lab will test strip your wire and provide proof-of-concept samples for your review free of charge. Just fill out our applications request form and send in samples of your wire to get started.

Recent Wire Stripping Software Updates

In 2019, we released the latest revision of Laser Wire Studio—an SQL database HMI that enables automation of laser wire processing recipes for the CMS Laser wire-stripping product line. Standard systems include a Windows 10/SQL HMI using Microsoft .NET Framework 4.5 programming language, and optional features include marking, stripping, cutting, prefeed and collection.

The HMI allows preparation of a wire job consisting of one or several groups. An individual group is a collection of wires with common data, such as wires of several different lengths that require the same strip lengths. Individual wires have setting adjustments for length of wire, strip distance from each end and window strip lengths placed anywhere along the wire. Once a wire has been defined, that wire can be duplicated any number of times.

Optionally, the system will support organized wire collection. The standard option includes a single or dual receptacle (bins or coilers) where each wire definition quantity is collected separately, or each group is collected separately. Custom collection is optional.