Accuracy and repeatability are frequently the guiding principles when vision systems are implemented. In today’s complex manufacturing lines, vision systems are an integral part of process accuracy, repeatability and quality control.

We previously wrote about the four key features that every vision system must incorporate: cameras, lighting, optics, and software controls. In this post, we’ll take an in-depth look at how these variables manifested in two real-world laser systems.

Two different clients came to us with different manufacturing needs, but a similar requirement: an automated process to provide vision system guidance to laser processes: marking and cutting. Each one presented its own unique challenges; our engineering team was able to design and build a custom system that added accuracy, efficiency, and speed to their overall manufacturing process. Let’s take a look.

System #1: Laser Marking and Cutting of PCBs

A client came to us seeking a laser-based solution for marking and cutting PCBs (small FR4 PCBs) from a large consolidated panel – a process known as singulation. Here’s an overview of the custom solution we successfully developed and delivered:

Laser:

An ultra-violet (UV) laser was chosen to produce high-contrast 2D marks and perform cuts on the FR4 PCB to produce singulated parts. Adjustable laser power allows the laser to perform both functions: Laser marking is set for lower power settings while cutting uses higher power settings to fulfill its application needs. With adjustable power, the system is able to make clean cuts through the board, or leave the pieces partially attached, depending on the client’s requirements.

Camera:

The goal of the camera is to align the laser marking locations and laser cutting path. In this case, we integrated a high-resolution camera to ensure accuracy in both laser processes.

Optics:

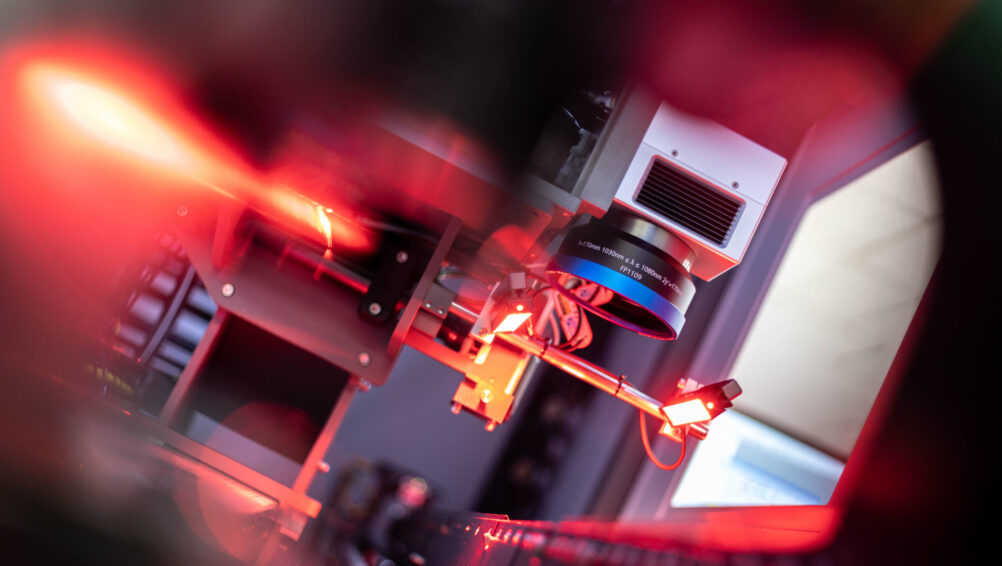

The vision system setup was configured on-axis, also called “through the optics” as the camera is integrated to use the same lens and galvanometer mirrors as the laser.

This configuration allows the camera to efficiently perform both key functions in this system: guidance and verification. In pre-processing, the vision system locates the fiducials to accurately align the laser to mark and cut out the pieces on the PCB board. In post-processing, the camera verifies the laser marked 2D code and confirms cut accuracy before moving forward to conduct the same process on the next part. With the on-axis configuration, this whole process is done in real-time enabling maximum efficiency.

Software:

The custom software designed by CMS supported the entire laser process in this system, including control of the laser’s power and confirmation of the laser marking accuracy.

Lighting:

This vision system design uses a versatile lighting system to provide optimum contrast for fiducial location and 2D matrix code content verification. Our engineers chose a bright field diffuse ring light for even illumination to ensure fiducial detection and proper contrast of the laser marked 2D code.

System #2: Barcode Decoding and Laser Marking Sensor Housings

We recently designed and incorporated a vision system into a laser-based solution for barcode decoding and laser marking of sensor housings located in conveyor pallets. Each conveyor pallet housed a single product; a through conveyor delivered the pallets to the system, which triggered the camera to perform a database lookup based on the vision system’s decoding of the serialized part barcode label.

Utilizing software with database stored procedures, the laser then imprinted the pallet with a laser marking file that included a 2D barcode, graphics, and regional markings. The system then needed to verify the laser marking to confirm accuracy. Let’s take a closer look at the vision system’s components:

Camera:

As we mentioned above, the vision system performed two functions in this system: pre-processing identification and post-processing verification. Utilizing a high-resolution camera maximized processing efficiency and speed.

Optics:

An off-axis at angle configuration was chosen for this system. The camera is angled such that the center the camera field matches the center of the laser field. This angled vision caused perspective distortion, but we corrected this distortion within the vision system calibration.

Lighting:

To properly illuminate the barcode on the curved laser marking area, a bright field diffuse lighting system was employed. The diffuse lighting provided uniform illumination across the sensor housings multiple surfaces and cylindrical region where a pre-applied barcode label was affixed.

Software:

Software played a key role in this laser marking solution. The vision system needed to communicate with the software to retrieve information on the laser marking process and verify location and content accuracy post-processing.

In addition, the software was employed to correct the perspective distortion resulting from the off-axis at angle optics configuration.

Final Thoughts

Vision systems are an integral part of the laser application process. The automated vision system is carefully integrated within both laser cutting and marking applications to ensure complete guidance throughout the process.

We hope you’ve enjoyed this series on vision systems. In the upcoming weeks, we’ll be taking an in-depth look at the several methods used for the depaneling of PCBs through laser processing within the electronics industry.

Do you have questions regarding vision systems within your laser applications? Contact us today to discuss your needs and specifications.