On our blog, we regularly write round-up posts about innovations within the field, such as our piece about important laser industry developments to look for in 2017.

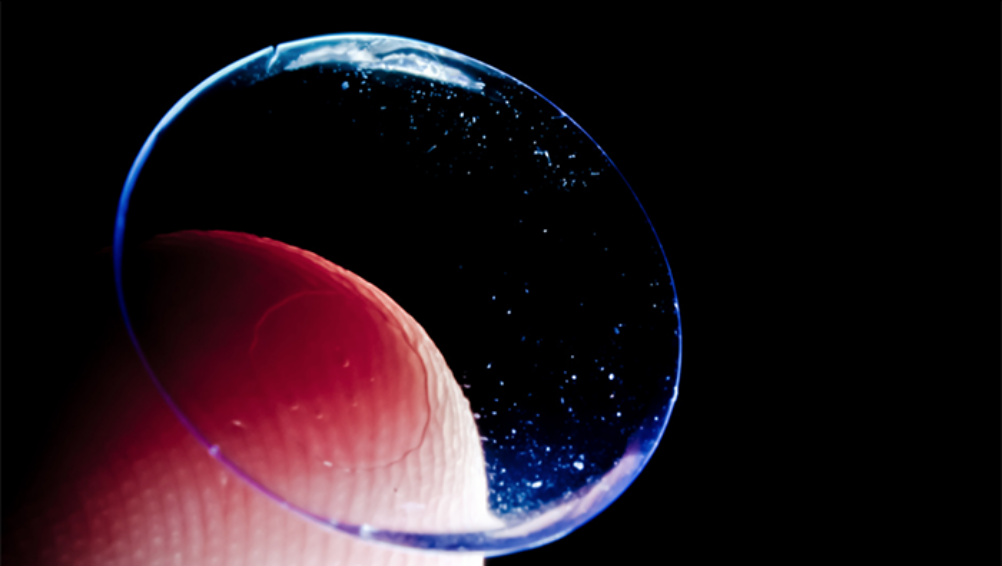

We also like to take time to feature specific applications for laser marking that diverse industries can utilize, with some of these applications, such as laser marking eye contacts, being ones you might not initially consider. Let’s take a look at some facts about the process.

Insights on Laser Engraving Eye Contacts

The type of laser system that is utilized for this laser marking process is usually a CO2 laser system, which is what TYKMA Electrox recommends.

For our customers, we have the capability to supply a custom laser system for laser engraving eye contacts depending upon specific requirements, and our Zetalase™ XL is also available for this purpose.

Using laser engraving for eye contacts can provide numerous benefits for companies, including:

- The mark creates no contrast, only an “imprint” look on the contact

- The process allows companies to do away with traditional printing, which eliminates the need for consumables like ink, and helps the environment

- Marking contacts allows for informational alphanumeric designations such as:

- Product codes and serial numbers for traceability

- Issue dates to ensure customers are aware of expirations

- External indicators which help users to insert contacts facing the correct way

As you can see, laser marking eye contacts can be advantageous to both businesses and customers alike.

Contact TYKMA Electrox Today

If you’re interested in a system for laser engraving contacts, be sure to reach out to our team today! We’d be happy to help you determine which system would work best for your applications.