Originally invented to print dials on wristwatches, pad printing has become a popular method for marking logos, text and other information on consumer, industrial and medical products. Also known as tampography or tampo printing, pad printing requires four elements: pad, cup or doctor blade, ink, and printing plate (cliché).

Like intaglio printing, pad printing requires an etched or engraved plate to be filled with ink. Excess ink is then removed from the top of the plate with a blade or cup. This is the opposite of relief printing where ink is applied to the raised surface of a block or plate, leaving the engraved areas with no ink. Intaglio printing has been used for centuries to print on paper and cloth by pressing the material directly on and into the engraving. With tampography — a form of gravure printing — there is an intermediate step in which a pad is pressed into the engraving to attract the ink and transfer the image onto the surface to be printed. This unique interaction of the tacky surface of the ink and the pad enables precise and quick ink transfer from engraving to pad to part. Modern pads are made of silicone and come in a variety of shapes and hardness (durometer) to accommodate different part geometries, print sizes, part materials and cliché types.

Laser Engraving Excels in Modern Cliché Manufacturing

Chemical etching, photo engraving and laser engraving are the three modern methods of manufacturing clichés. Chemical etching of steel plates has been employed the longest, and it produces highly detailed and durable etchings. Typically, these plates are not made on-site at manufacturing facilities and must be ordered. Photopolymer clichés can be created within manufacturing facilities without the environmental issues associated with chemical etching, but these plates are only durable enough for small and medium runs. Laser engraving can produce highly detailed images on a variety of plate materials without using dangerous chemicals. Laser cliché engraving is a computer-to-plate (CTP) process: Once the parameters for a specific type of plate are known, creating plates for a new project only requires artistry — not cliché manufacturing expertise.

There are four basic types of plate materials used for laser etched plates: polymer, steel, hard anodized aluminum and ceramic. Polymer coated plates can have a substrate of either steel or aluminum, and they exhibit a durability of less than 100,000 impressions. The engraving only takes place in the 30- to 50-micrometer thick polymer. Steel cliché plates are made of ground high-grade tool steel, with or without some chrome, and they can be made thin (0.5 millimeters, typical) or thick (10 millimeters, typical). They are good for production, capable of providing over 500,000 impressions for a thick plate. Hard anodized — or hard coat — aluminum and ceramic plates are usually thick and offer the best durability with over 1 million impressions per side. Like polymer coated plates, the hard coat should be thicker than the etch depth.

Using Lasers to Engrave Clichés

CO2, fiber and ultrafast lasers can be used for engraving clichés. Polymer-coated plates can be engraved with CO2 or fiber lasers. Some coatings work with either laser, but coatings specific to one or the other are common. Fiber lasers can produce engravings with much finer detail than CO2 lasers due to their shorter wavelength and smaller spot size. Neither of these lasers are recommended for engraving steel or ceramic plates due to either poor coupling, or excessive melting and raised edges that would require extra steps to remove.

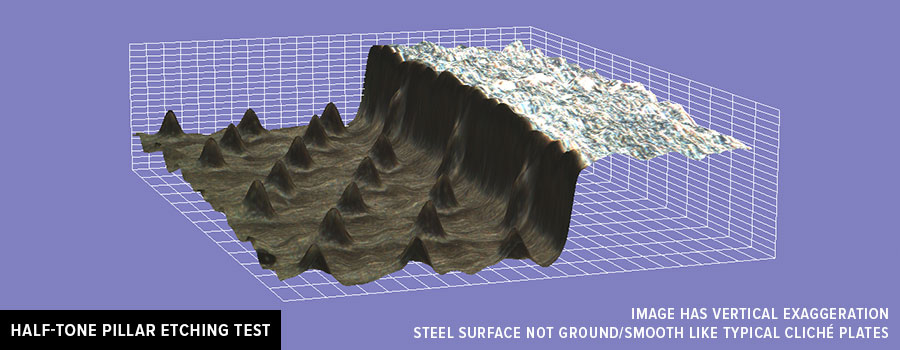

Ultrafast lasers (picosecond and femtosecond lasers) can produce steel and ceramic cliché plates to the same quality, precision and resolution as chemical etching. Engraving with ultrashort pulses leaves no raised edges on the surface of the plate. After washing off some loose debris, the plates are ready to be used. Typically, flat engraving depths of 22 +/- 2 µm are standard, but variable-depth (stepped and contoured) and half-tone pillars are also possible.

Picosecond and femtosecond lasers come in a variety of powers and wavelengths. Shorter wavelength lasers (green and ultraviolet) produce much smaller spot sizes than near infrared (NIR) fiber lasers, so engravings with much higher resolution can be made. A feature size and locational accuracy of 10 µm is typical of Control Micro Systems’ precision cliché engraving systems. NIR ultrafast lasers have larger spot sizes but offer more power, and therefore faster engraving, at a lower cost. Lasers with higher pulse energies can be used for other processes such as high aspect drilling, sheet cutting and deep engraving. Optional features such as integrated CMM probes and laser height profilers ensure every plate is ready for printing.

Cliché Plate Laser Etching System With Femtosecond Laser

If you are looking to bring cliché etching in-house, our engineering team is happy to assist with designing a solution to meet or exceed your production requirements. Contact us today to get started with your next high-tech solution for your cliché printing process.

For more information about ultrafast laser processing, visit our capabilities page or contact us.