Laser welding of plastic polymers has many advantages over traditional welding methods. These benefits allow you to weld complex part designs and path variations without the challenges of other welding methods, such as fixed weld paths, mechanical stress on sensitive parts due to direct contact and a fixed heat input rate. Laser welding overcomes all of these challenges.

At Control Micro Systems (CMS), we have extensive experience designing and manufacturing laser welding systems for all types of applications over many industries. Our engineers can help you implement laser technology to weld plastic polymers and take advantage of its many benefits, such as:

- Flexible weld pattern. Galvanometers direct the focused laser beam to allow for programmable weld patterns. Software controls can be used to input virtually any 2D weld path for complex designs, and these patterns can be quickly changed for each part without the need for replacement parts. Further automation can be integrated onto the system to achieve 3D weld paths, as required.

- Precise weld location. The laser’s focused spot ensures precise heat control. Spot size, focus depth and laser settings can be tuned to minimize heat-affected zones (HAZ). This is particularly advantageous when welding small parts that require detailed welding zones. It is also beneficial in cases where welding parts with channels or other important functional features cannot be melted during the welding process.

- Non-contact welding. Laser-welding plastics is a non-contact process. The laser energy is absorbed by the part, and heat is directed to the required locations. Other welding methods require direct contact with a heated element and use only heat conduction to weld the polymer. The laser welding process does not require replacement parts, and it puts less mechanical stress on parts than other methods.

- Automation friendly. Laser welding can be automated easily since all aspects can be controlled via a computer. Camera vision can find — and even track — weld paths, and laser position can be directed in real time to adjust to these found positions. Other motion components, such as linear motion tables, rotary stages and robots, can also be integrated for complete parts handling and automation. One laser welding system setup can often be designed to weld a variety of part types by programming different automation processes.

- Seam quality. Depending on the materials being welded, laser welding often achieves smooth, visually appealing weld seams that do not require any post-processing. Hermetic seals and strong weld strengths are also possible when using lasers to weld plastic polymers.

- Transparent plastic laser welding, also known as clear-on-clear welding. The medical industry often uses specific laser technologies to weld two transparent plastics together with no additives required and without color change.

The most important consideration for any welding application is ensuring that the parts are in intimate contact at the weld location. This can be achieved through specific part design or by designing fixtures to hold plastics together tightly during welding. Our engineers will be happy to discuss this option with you.

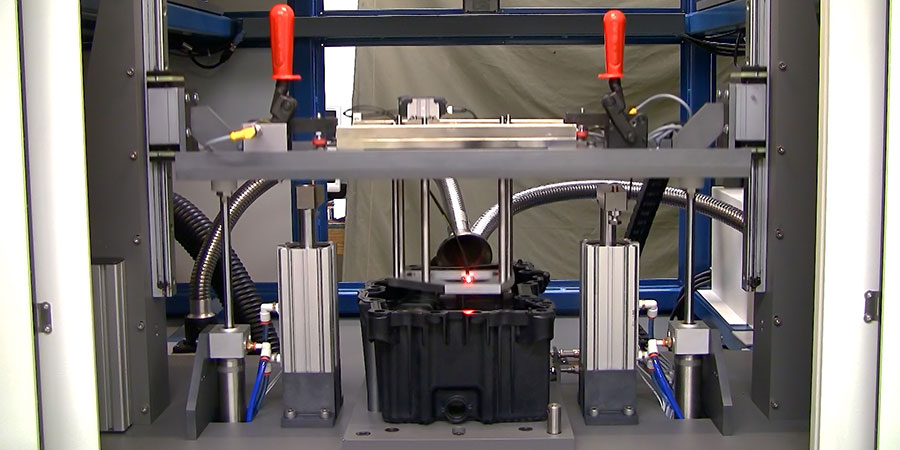

Video: Laser Welding Plastic Transmission Pans

If your application is particularly complex, we can also discuss further laser welding research and development (R&D) options. Our Applications Lab engineers and mechanical design engineering team can work with you to develop a laser welding system customized to your research and eventual production requirements. We can also develop a general laser welding R&D system for you if you would like to explore this technology yourself.

Contact us today to begin your no-cost sample evaluation!