As many companies and industries have discovered over the years, the benefits of laser marking, etching, and engraving are widespread, with precision, speed, reliability, and cost effectiveness all being key attributes of laser systems.

We’ve previously touched on laser marking’s benefits over processes like dot peen marking, electrochemical marking, and inkjet marking, but in this post we wanted to highlight one major selling point for laser systems, namely, their 3D marking capabilities.

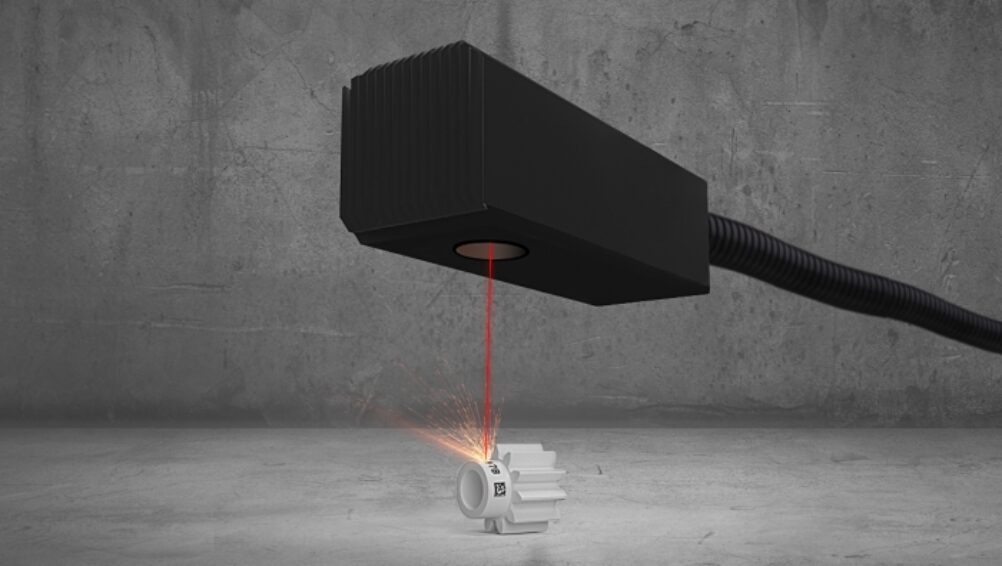

3D Laser Marking

Learning to 3D laser mark your parts is quite simple, with the process sharing many aspects of 2D laser marking. Our Zetalase™ XL laser marking system utilizes our Minilase™ Pro 3 software which lets operators quickly and easily design, edit, and select 3D laser marking programs.

Just like with 2D laser marking, 3D laser marking provides a computer-controlled beam that supplies micron accuracy and eliminates operator errors. Implementing a 3D laser marking system into your operations can bring with it a host of advantages, which we’ll examine below.

The Benefits of 3D Laser Marking

Utilizing a 3D laser marking system can supply your company with a variety of benefits, including:

- Diverse Marking Capabilities – While 2D laser marking provides significant versatility for applications, 3D laser marking expands them even greater. When using 2D marking on a non-flat surface the mark can become faded or distorted, but 3D marking allows you to mark on diverse surfaces, including uneven ones, maintaining a clean presentation of text, graphics, logos, and serial numbers. Some surfaces capable of being marked include:

- Cones

- Cylinders

- Spheres

- Concave surfaces

- Convex surfaces

- Slanted/sloped surfaces

- Triangular surfaces

- Ideal for Molds – For companies that regularly utilize molds or plastic injection moldings as part of their operations, 3D laser marking is particularly useful because of the concave and convex capabilities listed above. Clean, clear markings or engravings can be made on such molds quickly and efficiently.

- Ability to Facilitate Stairstep Marking – 3D marking excels at marking parts that feature a stairstep portion. Normally, when using 2D laser marking, an operator would need to alter the z-axis to change the laser’s height. But during 3D laser marking the height compensation is changed very quickly, allowing for stairstep marking without any axis motion.

- 3D Computer Modeling – By utilizing 3D laser marking software like our Minilase™ Pro SE software, operators are able to import any 3D model into their system, along with graphics and logos, allowing for a wide variety of potential applications. Once you have determined exactly how you want your part marked the system will follow the 3D model and render a clean, crisp mark on your finished piece in a 100% correct geometric reproduction.

Additionally, our Zetalase XL laser marking system can dynamically adjust the focus of the laser beam up and down up to 100mm max, mark tall and large parts through numerous configurations, allow for programmable focal height adjustment and more.

Customers can also acquire the optional full-size rotary device which can facilitate 360º radial marking around a round part or cylinder.

On top of all of these applications and benefits, it’s worth remembering all of the diverse materials that TYKMA Electrox’s MOPA fiber lasers are able to mark, etch, and engrave upon. Materials include:

- Steel

- Stainless steel

- Titanium

- Aluminum

- Brass and copper

- Nickel-plated materials

- Galvanized materials

- ABS plastics

- Polyethylene

- Glass-filled plastics

- Various other plastics

- Anodized aluminum

- Painted materials

- Black oxide

- Various other coated materials

- Carbide

- PCD

- Other synthetic materials

Considering a 3D Laser Marking System? Reach Out to Us!

If you’re thinking about adding a 3D laser marking system to your operations and reaping the benefits of all it can provide, be sure to contact our team. We’ll discuss options with you, as well as your future applications, to help you determine the best system for your business.