Manufacturers looking to upgrade their equipment with modern, laser-based solutions often may be unfamiliar with the measures needed to ensure operator safety and corporate culpability. This is understandable given the numerous online videos of unsafe laser use. However, current regulations and expert laser suppliers take a lot of the guesswork of implementing a safe laser system. Here’s how you can modernize your systems and be confident that your laser system meets prevailing safety standards.

Understand the Safety Classifications

The FDA’s Center for Devices and Radiological Health (CDRH), along with the International Electrotechnical Commission (IEC), provide standards and regulations pertaining to the building, classifying and labeling of lasers and laser systems. Lasers and laser systems built or imported in the United States must be classified under the CDRH, or in some instances, the IEC system.

The FDA (and IEC) have four main classes (I to IV and a few subclasses) of lasers and laser products. Among the four classes, Class IV is the most dangerous. Class I and Class IV are the most important classes for industrial equipment and are characterized by the Code of Federal Regulations (CFR) Title 21 as follows:

- Class I laser product means any laser product that does not permit access during the operation to levels of laser radiation in excess of the accessible emission limits contained in table I of paragraph (d) of this section. Class I levels of laser radiation are not considered to be hazardous.

- Class IV laser product means any laser that permits human access during operation to levels of laser radiation in excess of the accessible emission limits contained in table III-B of paragraph (d) of this section. Class IV levels of laser radiation are considered to be an acute hazard to the skin and eyes from direct and scattered radiation.

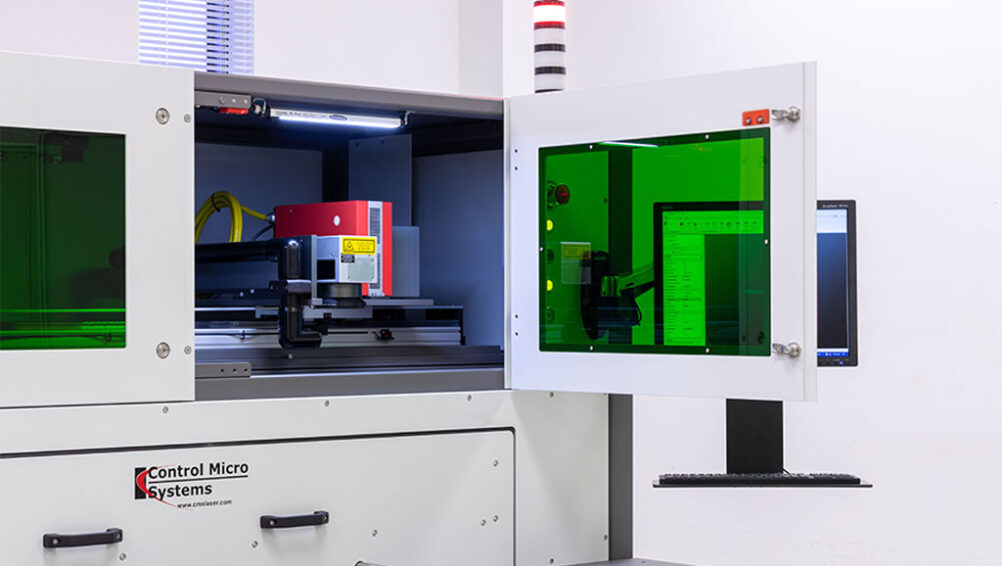

Many “turn-key” systems have built-in safeguards that seal and interlock lasing areas to prevent radiation from escaping when parts enter the system so operators can work without additional laser personal protection equipment (PPE). Class I systems include built-in safeguards along with proper inside and outside labeling. They also incorporate a Class IV laser which may not include a safety controller; therefore presenting safety risks to users who do not wear personal protective equipment. The end user must therefore ensure that all safety regulations and reporting are met.

So How Can an End-User Be Sure Their Laser System Is Safe?

When it comes to making sure you implement a safe laser system keep the following tips in mind:

- Look for CDRH Class I compliance. The system’s lasing areas should be sealed, interlocked and labeled. This is the safest type of industrial laser.

- Meet other electrical and mechanical requirements. The system should meet all other safety requirements and labels regarding electrical lockouts, E-stops, pinch points, mechanisms and lighting.

- Choose an experienced and knowledgeable system supplier. Not all laser system vendors are the same. Be sure to evaluate suppliers according to their experience and knowledge. CMS Laser has decades experience as a comprehensive integrator of laser systems for a wide range of industrial applications and includes many Fortune 100 and 500 companies among its clients. CMS certifies all its laser systems, whether Class I or Class IV. Our systems come with the certification “This product complies with 21 CFR 1040.10 and 1040.11 except for conformance with IEC 60825-1 Ed. 3., as descripted in laser notice 56 dated May 8, 2019”.

By implementing these and other measures, you can significantly lower your risk of operator injury and company liability while enjoying the promise of modern, efficient production using laser-based equipment.

For more information, visit www.cmslaser.com.