Lasers play an integral role in our society. No doubt one of the most important innovations of modern times, the laser is used across many different industries, including in such diverse fields as automotive, aerospace, medical, oil & gas, electronics and more.

The laser has evolved significantly since Theodore Maiman created the first working system for the technology in 1960, using ruby as a lasing medium that was stimulated with high-energy flashes of intense light from commercial flash lamps.

In the early years of the laser, most applications were found in the defense and industrial sectors, but as technology evolved, the laser expanded into many other industries and began to be used in varied applications.

Among these innovations is the invention of the MOPA laser, which has the capability to mark, etch and engrave products for identification, personalization or decorative purposes.

Exceed Your Production Expectations with a Laser Engraving System

What Is a MOPA Fiber Laser and How Does It Work?

Although there are many laser systems on the market today, the MOPA fiber laser system is one of the most innovative and technologically advanced systems you can find.

In order to fully understand what a MOPA fiber laser is, we must first dissect it into two parts: the MOPA technology and the actual laser system.

A Look at MOPA Technology

The term MOPA is actually an acronym for Master Oscillator Power Amplifier. This type of technology was a breakthrough in DUV light source design.

In traditional, single-chamber light sources, there is a trade-off between bandwidth and power, forcing you to choose between compromising either performance or cost effectiveness. But with MOPA technology, you no longer have to compromise and can get an incredibly efficient system for your investment.

The MOPA design has two gas discharge chambers: the master oscillator and the power amplifier.

- The master oscillator generates light with a low amount of energy in a tight spectrum

- Following this action, the light is then passed through the second chamber, the power amplifier, which intensifies the light to reach the necessary power levels

What is a Fiber Laser?

Fiber lasers are similar to their various counterparts in the laser industry, except the active gain medium is made up of an optical fiber with doped rare-earth elements. These elements may include erbium, ytterbium, neodymium, dysprosium, praseodymium and thulium.

These types of lasers use less energy and take up less space than other laser systems, saving you money and helping your business run more efficiently. They still, however, deliver high-quality markings, etchings, and engravings, meaning you don’t need to sacrifice anything.

The MOPA fiber laser is the best of both worlds.

As with all lasers, the process of how a MOPA fiber laser begins is the same. In order to create the light, you need to get the atoms in an excited state. As they move, they create a weak light that becomes more concentrated as more energy is added. Once this beam of light is created, it is amplified in some way to produce a focal point.

In MOPA lasers, an optical amplifier is used to create the focal point.

This is a configuration that consists of a master oscillator, which is a single-frequency laser used to inject lock one or several other lasers, and the optical amplifier.

The master oscillator produces a highly coherent beam, which is then amplified by the optical amplifier to increase the output power while preserving the main properties of the oscillator.

If it also contains a fiber amplifier to boost the output power, these types of laser systems may also be referred to as master oscillator fiber amplifiers (MOFA).

With the ability to modify and increase output power without changing the geometry, shape or operation principle, MOPA fiber lasers are the most popular way to achieve power scaling.

The Differences Between MOPA Fiber Lasers and YAG Lasers

YAG lasers and MOPA fiber lasers both have the capabilities to mark, etch and engrave on a variety of surfaces and materials. YAG lasers are outdated and outclassed when compared to MOPA lasers, though, as MOPA lasers offer the highest beam quality, long diode life, and more.

Though the two types of laser systems operate similarly, more and more companies are discovering the competitive advantage to using MOPA fiber laser systems instead of their outdated counterparts.

YAG Lasers

Also known as flash lamp or lamp-pumped lasers, YAG lasers utilize a bulb as a pumping mechanism and a YAG crystal as the gain medium. These both reside in an optical resonator, typically a gold-plated cavity, which reflects the light and helps with the process of creating the laser light.

Although many companies still use these types of laser systems, they are considered to be outdated and lack many of the advantageous qualities you will find with a MOPA fiber laser system.

For example, the bulbs for YAG lasers have a short lifespan and require frequent replacement. They also create large amounts of heat, therefore requiring water-cooling measures.

The YAG lasers are also very inefficient and are prone to common misalignment and adjustment problems.

MOPA Fiber Lasers

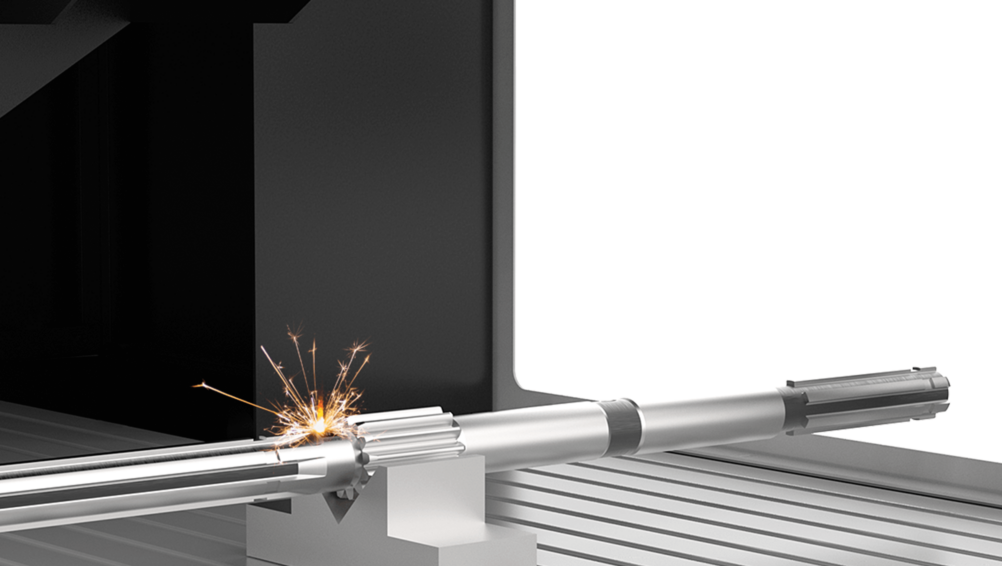

Unlike YAG lasers, MOPA fiber lasers utilize semiconductor diodes as the pumping mechanism and a doped fiber optic cable as the gain medium. For these fiber lasers, the doped fiber optic also serves as the resonator.

MOPA fiber lasers are much more reliable and efficient than previous laser technologies. With these laser systems, you know you are getting the best technology on the market.

The Advantages of a Fiber Laser Marking System

There are many advantages to choosing a MOPA laser system beyond just the reliability and efficiency of the machines.

Other advantages of these fiber laser machines include:

- Highest beam quality

- Air-cooling with high ambient air temperature operating capabilities

- Very efficient operation with low power consumption

- A virtually maintenance-free design

- Longest diode life (up to 100,000 hours)

- Extended warranties surpassing other technologies

- The MOPA design allows for maximum application flexibility

- High peak power and long pulse durations allowing for high-speed aggressive marking and deep engraving applications

- Easy to integrate within your operations

- Easy to service, with 24/7 customer support supplied by TYKMA Electrox, along with downloads, training, and tutorials

- A rugged, compact design

- Invulnerable to the misalignment and adjustment problems found in YAG lasers

TYKMA Electrox’s Industry-Leading MOPA Fiber Lasers

At TYKMA Electrox, we strive to continuously provide our customers with the most innovative and high-quality laser marking, engraving and etching technology available. This means that each of our laser marking systems comes equipped with the latest MOPA technology.

With our MOPA laser marking machines, you receive maximum flexibility and better pulse duration control no matter the project. Our technology allows you to utilize selectable waveforms and an expansive frequency range, offering greater peak power at high frequencies.

This also allows you to mark, etch or engrave on a wider variety of surfaces. Some of the materials and surfaces on which our machines mark include:

- Steel

- Aluminum

- Titanium

- Brass and copper

- Painted materials

- Black oxide

- Polyethylene

- ABS plastic

- Carbide

- PCD and so much more!

The added MOPA technology allows our machines to also mark on difficult materials such as gold and nickel plating, as well as a variety of painted and anodized surfaces. With MOPA technology, you get more enhanced and definitive marks than you would with any other type of laser marking machine.

Put MOPA Fiber Lasers in Your Facility Today

TYKMA Electrox has a long-standing history of providing industrial laser marking and engraving solutions to companies all over the world, so let us do the same for you. If you would like to learn more about our diverse line of fiber laser marking systems, contact us today!